This fiber is a specially designed and patented Enviro-Stasis ™ fiber.

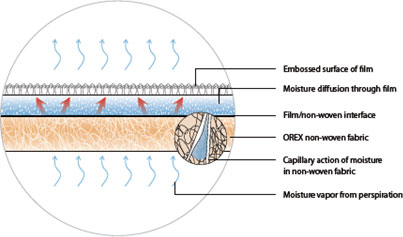

Orex Ultra is a combination of Orex nonwoven and special film.

The inner Orex nonwoven fabric layer has good air permeability, is soft, does not stick to the body even when sweating, and absorbs sweat easily. The outer film layer dissipates the absorbed moisture to the outside. In particular, the surface of the film layer is embossed and is effective for moisture discharge to the outside. In addition, the film layer is extremely resistant to blocking particulate contaminants from the outside.

OREX/RADECO TECHNICAL SALES

- Overview

- Product specifications

- OREX Product Characteristics

- OREX Product Information

- Radeco Product Information

-

Technical sales

- Purchase procedure

- Request method

- Request for quotation

- Request details check

- Introduction of PVA

processing technology

OREX/RADECO TECHNICAL SALES

HOME > OREX/RADECO TECHNICAL SALES > Product specifications

- · Nonwoven-type protection products made of PVA (Polyvinyl alcohol)

- · Protective materials that are discarded after use can be treated by dissolving

- · Can be used as protection products in nuclear power plants and hospitals

- · More than 80% of US Nuclear Power Plants are using it and China / Mexico / UAE are being introduced and piloted

- · Excellent strength, absorbency, breathability and waterproof

- · Has more chemical resistance, fire resistance, antistatic ability and warmth than existing cotton products

- · Manufactured in nonwoven and film form

A. OREX Ultra Enviro-Stasis™

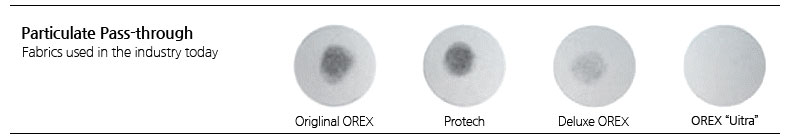

B. Particle permeability test

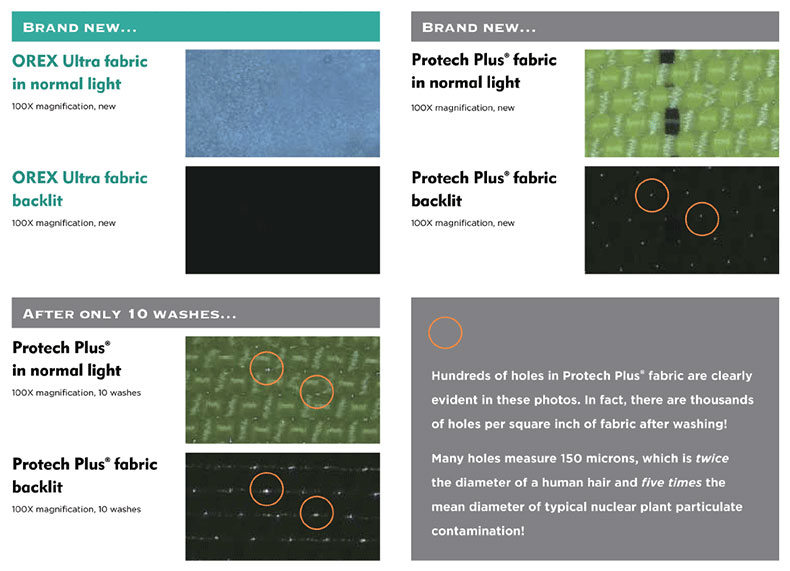

This picture shows the particle protection performance test of the Orex Ultra protective clothing. Put the protective clothing fibers on the bottom of the open barrel, put graphite powder and glass beads in the barrel, and then perform a falling motion from top to bottom. Then the graphite powder passes through the fibers under the barrel and leaves marks on the white paper on the bottom. The smaller the number of graphite marks, the more graphite powder will not pass through the fibers and the better the protection against particles.

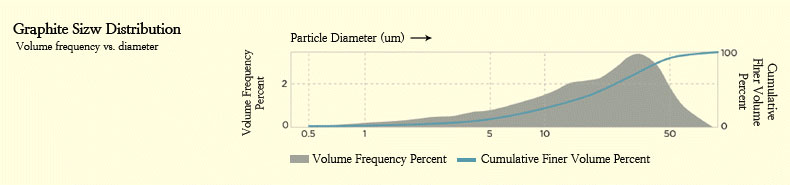

This graph shows the particle size distribution of the graphite size and volume used in the above experiments. The graphite powder used is about 0.5 ~ 90um in size, and the distribution of the amount of each particle is as shown above. The graphite powder used in the above particle penetration test indicates that it is the main radioactive contaminant particle size in the nuclear power plant.

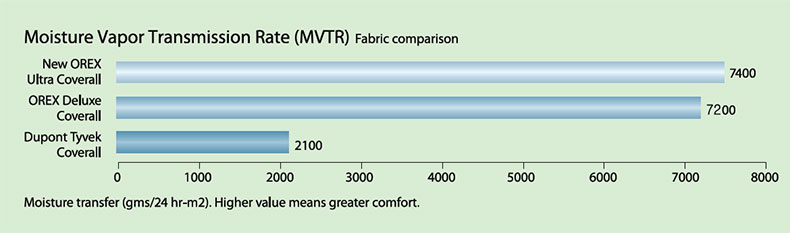

C. Repellent performance test (sweat discharge capacity)

This graph shows the water repellent performance (sweat discharge capacity) of each fiber. When tested under the same conditions, the Orex Ultra emits about 7400 g/m2 of moisture to the outside for 24 hours, and Dupont Tyvek emits about 2100 g/m2 of moisture to the outside for 24 hours. The Orex Ultra showed a water repellency of 3.4 times higher than that of Dupont.

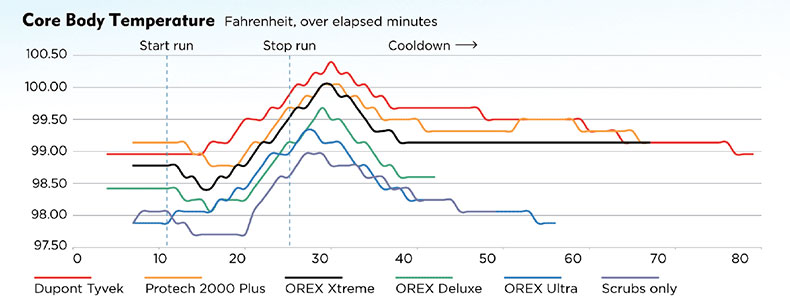

D. Body temperature change test (heat stress)

This graph is a graph showing changes in body temperature under difficult working conditions while wearing each protective suit. The test was carried out with jogging for 16 minutes at a speed of about 8 km/kr, which consumes about 800 kcal/h and belongs to the hard labor category. As a result of testing, the Orex Ultra protective suit has good sweat evacuation capability, so the body temperature is maintained properly and the recovery time is fast. DuPont Tyvek, on the other hand, had poor breathability and sweat discharge, resulting in increased worker heat stress and a very slow recovery rate.

E. Fiber material

OREX protective clothing is non-woven fabric. Protective clothing materials such as cotton, which are generally used, have holes between them, which makes it difficult to effectively block contaminated particles, and it is difficult to expect high protection performance because the holes are widened during washing.